If you want to spot aluminum wiring in your house, look closely at the wiring itself. Aluminum wiring is marked with “Al” or “Aluminum” on the insulation and has a lighter, silvery color compared to copper.

You might find aluminum wiring in older homes built from the 1960s to the 1970s. During that time, builders used aluminum as a cheaper alternative to copper.

Knowing if your home has aluminum wiring is important because it can cause safety issues if not handled right. Check where your wiring connects to outlets, switches, or the breaker box to help identify it.

If you ever feel unsure, get a professional to take a look.

Understanding Aluminum Wiring

Aluminum wiring has unique properties and a history that affect how people use it in homes. Knowing what it is, how it differs from copper wiring, and why some houses have it will help you identify it and understand potential issues.

What Is Aluminum Wiring

Aluminum wiring is electrical wire made from aluminum metal instead of copper. It is lighter and less expensive than copper, which made it popular in the 1960s and 1970s.

You’ll often find aluminum wiring in older homes built during this time. Aluminum wiring is usually larger in size than copper wiring because aluminum doesn’t carry electricity as efficiently as copper.

Aluminum wiring looks similar to copper but has a dull, grayish color rather than a shiny reddish color. If you see wire that is light gray or silver, it may be aluminum.

Difference Between Aluminum and Copper Wiring

The main difference between aluminum and copper wiring is their material and how well they carry electricity.

| Feature | Aluminum Wiring | Copper Wiring |

|---|---|---|

| Conductivity | Lower conductivity | Higher conductivity |

| Weight | Lighter | Heavier |

| Cost | Less expensive | More expensive |

| Flexibility | More prone to break | More flexible and strong |

| Appearance | Dull, grayish color | Shiny, reddish color |

Aluminum wires expand and contract more with temperature changes. This can cause connections to loosen, which may create fire hazards if not checked regularly.

Why Aluminum Was Used in Homes

During the late 1960s, a copper shortage made copper prices high. Aluminum became a cheaper alternative for electrical wiring.

Builders and electricians used aluminum wiring to save on costs. It was especially common in branch circuits that connect outlets and lights inside homes.

While aluminum wiring saved money upfront, it has some problems like increased risk of loose connections and overheating if not installed properly.

Signs You May Have Aluminum Wiring

Aluminum wiring has clear clues you can look for in your home. These include the age of your house, labels or markings on the wires, and the look of the wires themselves.

Homes Built During Certain Years

If your home was built between the mid-1960s and early 1970s, it’s more likely to have aluminum wiring. During that time, aluminum was used because it was cheaper than copper.

Builders stopped using it widely after the early 1970s due to safety concerns. So, if your home falls in this date range, check for aluminum wiring.

Even if your house is newer, aluminum wire might still be present if there were upgrades or additions during that period.

Common Warning Labels and Markings

Aluminum wiring often has specific labels or stamps on the insulation. Look for words like “AL” or “Aluminum” printed on the wire’s outer layer.

You might also see the mark “ALR,” which stands for Aluminum Revised. This means the wire meets newer safety standards.

Your breaker panel may have stickers or labels warning of aluminum wire inside. These warnings help electricians handle the wiring safely during repairs.

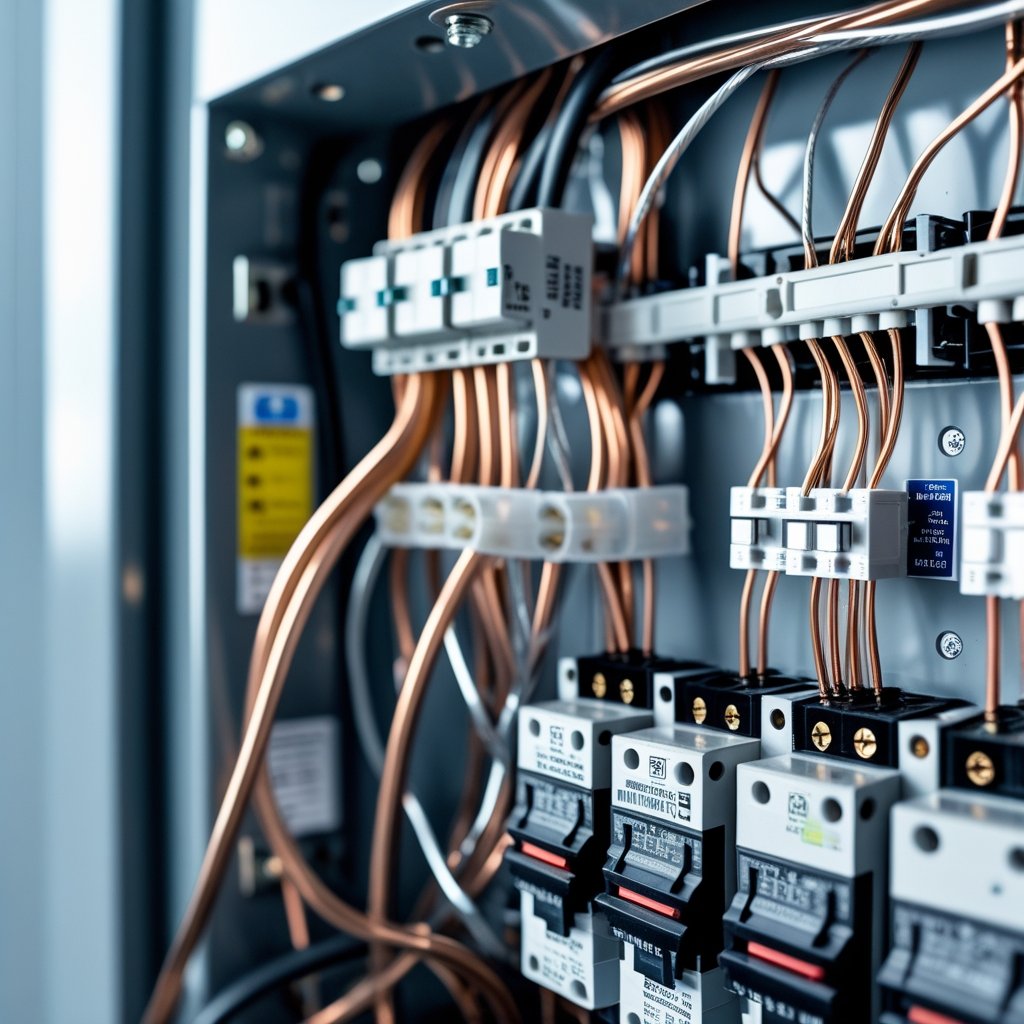

Visible Characteristics of Aluminum Wires

Aluminum wires usually look different from copper. They are lighter in color, with a dull silver or gray finish rather than the bright reddish tone of copper.

If you can safely check your electrical outlets or light fixtures, look at the wires inside. Aluminum wires are usually thicker than copper ones of the same rating.

Be cautious if you see any signs of overheating, like melted insulation or a burning smell. These could mean the aluminum wiring is aging or damaged.

How to Inspect Your Electrical System

To inspect your electrical system for aluminum wiring, check your electrical panel, look at wiring in outlets and switches, and use the right tools. This helps you spot aluminum wiring safely and avoid risks.

Checking Your Electrical Panel

Start by turning off power at the main breaker to stay safe. Open your electrical panel and look at the wires connected to the breakers.

Aluminum wiring is usually silver or dull gray, while copper wires are bright orange or reddish. Check the breaker labels, too.

Some panels may note if aluminum wiring is present. Look for signs of wear, such as corrosion or overheating, around wire connections.

Avoid touching wires directly. If you see any damaged or loose wires, call an electrician.

Identifying Wiring At Outlets and Switches

Remove the cover plates from outlets or switches after shutting off power. Look directly at the wires connected to the terminals.

Aluminum wires are thicker and lighter in color than copper. You might see “AL” stamped on the wire insulation or cable jacket.

Be careful if you notice any blackened or melted spots. This can mean overheating, which is common with aluminum wiring if not handled properly.

If unsure, ask an electrician to check or label the wiring for you.

Tools Needed for Identification

To spot aluminum wiring, keep these tools handy:

- Voltage tester: Ensures power is off before you start.

- Flashlight: Helps you see inside dark panels or boxes.

- Wire strippers: For safely exposing wire ends if needed.

- Multimeter: Measures conductivity and can help identify wire types.

- Stud finder with wire detection: Useful for locating hidden wiring in walls.

Using these tools helps you safely find and confirm aluminum wiring in your home. If you don’t have these tools, or if anything looks damaged, get professional help.

Safety Considerations When Checking Wiring

Checking for aluminum wiring means handling electrical parts that can be risky. Prepare carefully and know when it’s best to get professional help to avoid harm and damage.

Precautions Before Inspection

Turn off power at the main breaker before you start to reduce shock risk. Always use a voltage tester to double-check that wires are not live.

Wear insulated gloves and use tools with rubber grips. Avoid touching exposed wiring with bare hands or metal objects.

Look for signs like discoloration or loose connections, but don’t force or pull on wires. Aluminum wiring can be brittle and may break or spark if handled roughly.

Keep a flashlight handy for better visibility in dark spaces. Never check wiring in wet areas or with wet hands.

When to Call a Professional

If you find wires that look damaged, brittle, or too old, call a licensed electrician immediately. Aluminum wiring can overheat or cause fire hazards if not treated properly.

Any electrical work involving aluminum wiring, like repairs or replacements, is best left to experts. They have special tools and experience.

If you notice flickering lights, warm outlets, or burning smells near wiring, do not try to fix it yourself. These are signs of serious problems that need professional attention.

Potential Issues Caused by Aluminum Wiring

Aluminum wiring can cause problems that affect your home’s safety and costs. These issues can lead to fire risks, damage to your electrical system, and complications with home insurance.

Electrical Hazards

Aluminum wiring is more likely to overheat than copper wiring. Aluminum expands and contracts more with temperature changes.

Over time, this can loosen connections in outlets, switches, or circuit breakers. Loose connections cause sparks or arcing, which can start electrical fires.

Signs of trouble include warm or discolored outlets, flickering lights, or the smell of burning plastic near wiring. Watch for these signs and have a licensed electrician inspect any aluminum wiring.

They can suggest repairs like adding special connectors or replacing the wiring to keep your home safe.

Insurance Implications

Homes with aluminum wiring might face higher insurance premiums or stricter requirements. Insurance companies see aluminum wiring as a higher fire risk because of the potential for overheating and connection failure.

Some insurers may ask for a professional inspection before offering coverage or may require updates to the wiring. If your home has aluminum wiring, notify your insurer to avoid issues with claims later on.

Keeping records of any upgrades or inspections can help you prove your home’s safety and possibly lower insurance costs. Always check with your insurance agent about how aluminum wiring affects your policy.

Steps to Take if You Find Aluminum Wiring

If you discover aluminum wiring in your home, handle the situation carefully. Keep track of what you find, get professional advice, and decide on safe actions to protect your home.

Documenting Your Findings

Note exactly where the aluminum wiring is located. Take photos or videos of the wires, outlets, and connections.

Write down any visible signs like discoloration, loose connections, or a burning smell. Create a simple list that includes:

- The rooms or areas with aluminum wiring

- The condition of the wiring and connections

- Any unusual signs such as warm outlets or flickering lights

This information will be useful when you speak to a professional or plan any repairs.

Consulting a Licensed Electrician

After documenting your aluminum wiring, contact a licensed electrician who has experience with this type of wiring. Aluminum wiring can pose a fire risk if not handled properly, so professional advice is critical.

Explain what you found and share your notes and photos. Your electrician can inspect the wiring in detail, test for safety issues, and recommend the best approach.

Avoid trying to handle repairs on your own because aluminum wiring requires special connectors and techniques.

Recommended Next Steps

After inspection, your electrician may suggest one or more of these actions:

- Repair using special connectors designed for aluminum wiring

- Replace aluminum wiring sections with copper wiring for safety

- Install CO/ALR-rated outlets and switches made for aluminum wiring

- Regular maintenance checks to monitor potential risks

Prioritize fixes that reduce overheating and loose connections. Always follow your electrician’s advice for safe repairs or upgrades.

Alternatives and Upgrades for Aluminum Wiring

If you have aluminum wiring in your home, consider options to improve safety and reliability. Upgrading or replacing aluminum wiring can reduce risks like overheating or poor connections.

Using the right materials and connectors keeps your electrical system safe.

Replacement Options

One common upgrade is to replace aluminum wiring with copper wiring. Copper is more durable and less likely to cause issues like overheating.

It also handles electrical current better and resists corrosion. Replacing all aluminum wiring can be a big job.

You might choose to replace only the most critical parts, such as wiring to outlets or switches. Hire a licensed electrician because they know how to handle aluminum safely.

Another option is to leave the aluminum wiring but cover it with copper pigtails. These short copper wires connect the aluminum wiring to devices, reducing direct contact and risk.

Aluminum-Compatible Connectors

If you keep aluminum wiring, use connectors made specifically for aluminum. These connectors help prevent corrosion and loose connections, which are common problems with aluminum.

Look for products labeled “CO/ALR” (copper-aluminum wire rated). They are designed to connect aluminum and copper wires safely.

Replace standard wire nuts with these special connectors wherever aluminum wires join with copper. Using aluminum-compatible connectors reduces fire hazards and keeps your electrical system stable.

Always follow manufacturer instructions and local codes when installing these connectors. If you are not sure, a professional electrician can help with the right materials and installation.

Frequently Asked Questions

You’ll learn how to spot aluminum wiring by its color and texture. You’ll also find out when it was mostly used and safe ways to check your home.

There is useful info about selling a home with aluminum wiring. You’ll also learn what it might cost to replace it.

You’ll get to know what single-strand aluminum wiring means and why it matters.

What are the visual differences between aluminum and copper wiring?

Aluminum wiring is usually silver or gray with a dull finish. Copper wiring has a bright, reddish-brown color and shines more.

Aluminum wires often feel lighter and softer than copper wires.

During which years was aluminum wiring commonly used in homes?

Builders mostly used aluminum wiring between the mid-1960s and early 1970s. It was popular because it cost less than copper.

After the 1970s, most builders switched back to copper.

How can I safely check if my house has aluminum wiring?

Look inside your electrical outlets or breaker panel. Always turn off the power first.

If you’re unsure, ask a licensed electrician to check. Using tools like a voltage tester without experience can be dangerous.

What should I know about selling a home with aluminum wiring?

You should disclose the aluminum wiring to buyers because it can be a safety concern. Some buyers may ask for repairs or replacements before buying.

Having an inspection report can help during the sale.

What is the typical cost to replace aluminum wiring in a house?

Replacing aluminum wiring usually costs several thousand dollars. The price depends on your home’s size and how much wiring needs to be changed.

It’s a good idea to get a professional estimate.

Can you describe single-strand aluminum wiring and its significance?

Single-strand aluminum wiring is a wire made from one solid piece of aluminum. It does not contain multiple smaller strands twisted together.

Older homes often used this type of wiring. Single-strand aluminum wiring can break or overheat more easily than other types.

These issues raise concerns about safety and electrical reliability.