Grounding an electrical panel is essential for ensuring the safety and proper functioning of your electrical system. By creating a direct path for excess electricity to flow safely into the ground, you protect your home from potential electrical surges and hazards. Without proper grounding, your electrical system can be vulnerable to faults that may lead to dangerous situations, including electrical shocks or fires.

Understanding the correct steps to ground your electrical panel can seem daunting. However, with the right guidance, it’s a manageable task that can significantly enhance your home’s safety. If you need help, Magnify Electric is here for you. Our team of licensed electricians specializes in residential and commercial electrical work, providing expert assistance whether you’re making basic upgrades or need full-scale installations.

Choosing Magnify Electric means you have a trusted partner to address all your electrical needs. From grounding your electrical panel to ensuring it complies with local codes, we prioritize your safety and satisfaction, making us the best choice for your electrical projects.

Understanding Electrical Panel Grounding

Electrical panel grounding is crucial for ensuring safety and reliability in your electrical system. It protects against potential electrical hazards, stabilizes voltage, and provides a safe pathway for excess electricity. Understanding the components and functions of grounding will help you maintain a secure environment in your home or business.

Purpose of Grounding

Grounding serves multiple purposes in an electrical system. Primarily, it offers a safe route for excess electrical current to flow safely into the earth. This route protects both equipment and individuals from electrical shocks, ensuring a stable voltage.

Grounding also dissipates electrical surges, such as those caused by lightning strikes or power fluctuations. These surges can damage sensitive electronic devices. By directing excess current away from equipment, grounding helps to extend the lifespan of your appliances and electronics.

How Electrical Grounding Works

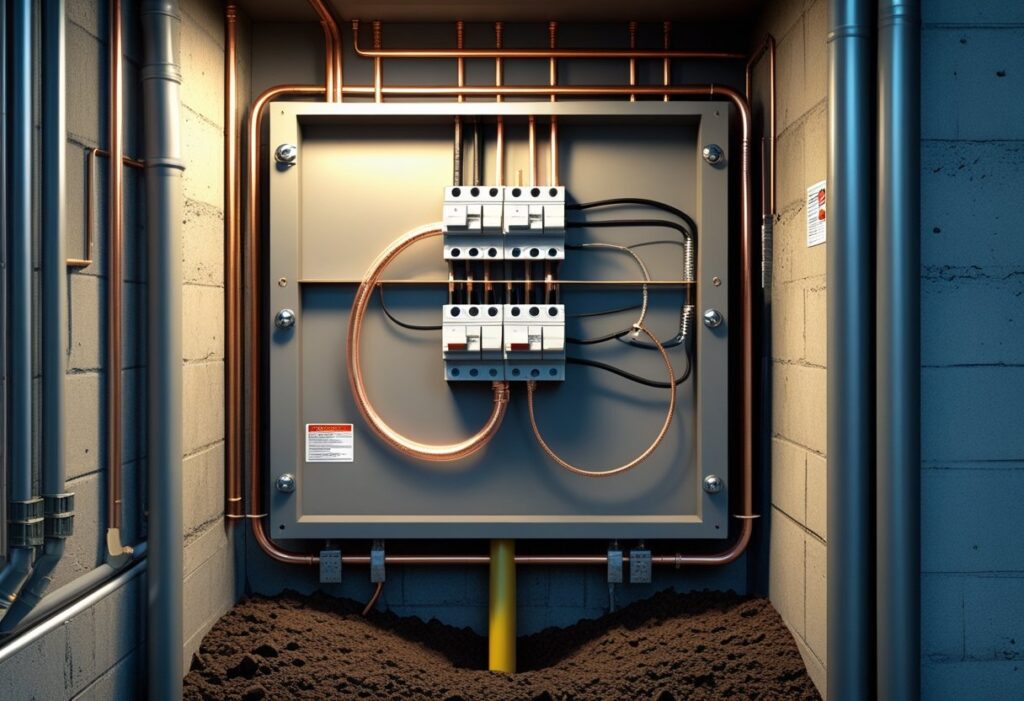

Electrical grounding operates by connecting your electrical panel to the ground using conductors and grounding rods. When excess electrical current occurs, it travels through this connection directly to the ground rather than through your devices. This action minimizes the risk of electric shocks or equipment damage.

This grounding system relies on conductive elements to transfer electricity safely. When faults occur, such as a short circuit, the grounding system efficiently directs the fault current away, allowing circuit breakers to trip and cut off power. Essentially, this mechanism protects both the user and the electrical system from potential harm.

Grounding vs. Bonding

While grounding and bonding are often used interchangeably, they serve distinct purposes. Grounding refers to creating a safe path for electric current to flow into the earth. In contrast, bonding connects various parts of your electrical system to ensure they share the same electrical potential.

Bonding prevents voltage differences between conductive surfaces, reducing the risk of electric shocks. For example, if metal equipment is bonded, it helps equalize electric potential with the grounding system. Both processes are vital for enhancing safety, but grounding directly protects against external hazards, whereas bonding focuses on internal system integrity.

Components of a Grounding System

Several key components make up a reliable grounding system. The main elements include:

- Grounding Rods: Installed in the earth, these rods connect directly to the electrical panel, providing a path for excess electricity.

- Grounding Wires: These conductors connect various system components to the grounding rods, ensuring effective electrical pathways.

- Grounding Plates: In some systems, conductive plates buried in the soil serve as an alternative to rods, distributing electrical current.

Each component plays a vital role in forming a complete grounding system, which is essential for operational safety. Trust Magnify Electric for all grounding needs, as our licensed electricians provide expert installation and service to both residential and commercial clients. Whether it’s a new system or modifications to an existing setup, we ensure that your grounding system is effective and compliant with standards.

Tools, Materials, and Safety Precautions

Grounding an electrical panel is essential for safety. Proper tools, materials, and safety precautions are critical for a successful installation. Understanding what you’ll need and the necessary steps to protect yourself can make this task simpler and safer.

Essential Tools for Grounding

You will require several essential tools to ground an electrical panel effectively. A voltage tester is crucial for checking electrical currents and ensuring the panel is de-energized before work begins. A wire cutter/stripper is needed to prepare the ground wire by cutting to the correct length and stripping the insulation.

A socket or wrench set is vital for securing connections at the grounding terminal. A drill may be necessary to create holes for grounding rods or to attach grounding lugs. Additionally, having a screwdriver set will help with any screws securing the panel or connections. Ensure that your tools are in good condition and appropriate for electrical work to avoid accidents.

Recommended Safety Equipment

Safety should always come first when working with electrical systems. Wearing safety goggles protects your eyes from debris or accidental sparks. Heavy-duty insulated gloves are necessary to prevent electrical shocks. Consider using hard hats as added protection against head injuries when working in tight spaces or near overhead lines.

Rubber-soled shoes are recommended to reduce electrical conductivity. You may also want to use a face shield if you’re working with tools that could create flying debris. Each of these items plays a vital role in protecting yourself while grounding your electrical panel.

Selecting Proper Materials

Choosing the right materials is crucial for grounding your electrical panel properly. You will need a grounding wire, typically bare or green copper, with the gauge specified by your local code or NEC (National Electrical Code).

Grounding rods should be made of copper or galvanized steel to ensure durability and conductivity. Other components include grounding clamps and lugs to secure connections securely. Make sure all materials comply with local codes and standards, ensuring reliable grounding. Magnify Electric’s licensed electricians can guide you in selecting the best materials for your specific project, ensuring safety and compliance.

Pre-Work Safety Steps

Before starting your grounding project, take decisive safety steps. First, ensure that the main breaker is turned off to eliminate power to the panel. Using a voltage tester, confirm that the power is indeed off before touching any wires.

Next, wear your safety gear, including gloves and goggles, to protect against electrical hazards. Be aware of your surroundings and ensure a clutter-free workspace to avoid tripping hazards. Always have a first aid kit handy, and know how to use it in an emergency. If you’re uncertain about any step, consult with a qualified electrician. For complete residential and business needs, Magnify Electric is ready to assist you with any electrical work you may encounter.

Step-by-Step Guide to Grounding an Electrical Panel

Grounding an electrical panel is crucial for safety and compliance with local codes. This process ensures that any excess electricity has a safe path to the earth, preventing electric shocks and damage to your home wiring system. Follow these steps for a successful grounding installation.

Shutting Off Power and Preparation

Before beginning, shut off the main breaker to cut power to the panel. This step is essential for your safety. Use a tester to confirm there is no voltage present in the panel.

Next, gather your materials. You’ll need a grounding electrode, grounding wire, a grounding bar, and tools like a drill, wrenches, and wire cutters. Ensure that the grounding wire is of the correct gauge based on your home wiring system. It’s advisable to read through your local codes about grounding requirements.

Finally, ensure your workspace is safe and organized to maintain a smooth workflow.

Installing Grounding Electrode and Conductor

Start by selecting a location for the grounding electrode, ideally within a few feet of your electrical panel. Common options include ground rods or metal underground water pipes. For rod installation, drive the grounding rod into the earth until it is flush with the ground.

Next, run a grounding conductor from this electrode to the grounding bar inside your electrical panel. Strip the insulation from both ends of the wire and connect one end to the grounding rod and the other to the grounding bar. Use appropriate connectors to ensure a solid connection.

Also, make sure to bury any exposed wire to protect it from potential damage.

Connecting Grounding Bar and Ground Wire

Locate the grounding bar within your electrical panel. This bar serves as the central point for all ground wires from your circuits. Connect your previously installed grounding wire to this bar using a terminal screw.

Ensure all connections are tight to facilitate a proper grounding system. You can use a torque wrench to ensure that screws are tightened to the manufacturer’s specifications. This will prevent any future issues due to loose connections.

After connecting, run the ground wires from your circuit breakers to this grounding bar. Ensure you follow the appropriate layout as per your home wiring system.

Testing the Grounding System

Once all connections are complete, it’s vital to test the grounding system to ensure it functions correctly. Use a multimeter to check the resistance of the grounding connection. A reading of 25 ohms or less is typically acceptable for effective grounding.

If the resistance is higher, additional grounding methods may be necessary. Ensure that the grounding system provides a safe path for stray electricity to dissipate into the earth.

If you need any assistance with this process or require further electrical work, consider choosing Magnify Electric. Our licensed electricians specialize in residential and commercial electrical solutions tailored to your needs.

Key Considerations for Code Compliance and System Type

When grounding an electrical panel, ensuring compliance with codes and standards is essential for safety and functionality. Understanding how NEC regulations apply and the differences between main and subpanels will guide you in making informed decisions. Additionally, special considerations for older homes require attention to detail, as existing systems may not meet current standards.

National Electrical Code (NEC) Grounding Requirements

The National Electrical Code (NEC) outlines specific grounding and bonding requirements to prevent electrical hazards. According to NEC Article 250, all electrical systems must have a reliable ground connection to divert fault currents safely, protecting both the system and its users.

You should establish a ground rod connected to the panel and use proper grounding conductors, ensuring a low-resistance path back to the earth.

Ground-fault circuit interrupters (GFCIs) may be required in areas exposed to moisture, such as kitchens and bathrooms, further enhancing safety. Compliance with these regulations is not just a matter of safety; it is often legally required. For assistance navigating these requirements, consider consulting with experts at Magnify Electric.

Grounding Main Versus Subpanels

Grounding methods differ between main panels and subpanels. The main panel serves as the hub for incoming electrical service and must connect to a grounding electrode system. This ensures your entire electrical system remains bonded.

For subpanels, however, the approach varies. A bonding jumper connects the neutral and ground bars in the main panel, but in subpanels, this bond should not exist. Instead, the subpanel requires its own ground connection to the earth.

Recognizing these differences is crucial for maintaining system integrity. Failing to adhere to these practices can lead to increased risk of electrical shock or fire hazards.

Special Considerations for Older Homes

Grounding in older homes often presents unique challenges. Many older systems lack modern grounding practices, which may expose you to higher risks of electrical faults.

You may encounter outdated wiring and insufficient grounding rods, which compromise safety. Upgrading these systems is vital, and you should inspect for any signs of wear or damage.

Ensure that any upgrades comply with current NEC standards, as they may differ significantly from older codes. If you’re unsure, contacting a licensed electrician from Magnify Electric for a comprehensive evaluation will ensure your home meets safety standards while providing peace of mind.

Common Issues and Troubleshooting

Grounding an electrical panel can present various challenges. Identifying improper grounding, addressing ground-fault conditions, and ensuring adequate testing are essential steps to maintain safety and functionality in your electrical system.

Recognizing Improper Grounding

Improper grounding can manifest in several ways. Common signs include flickering lights, tripped circuit breakers, and appliances malfunctioning. If you notice that your ground-fault circuit interrupter (GFCI) trips frequently, it may indicate an underlying grounding issue.

Check your connections to ensure that ground wires are securely connected to the panel. Inspect for any signs of corrosion or wear on grounding rods. Regular maintenance can prevent these issues from escalating, ensuring a safe environment for your electrical appliances.

Addressing Ground-Fault Conditions

Ground-fault conditions can pose serious safety risks, often leading to electric shocks or equipment damage. These conditions usually arise when there is a break in the grounding path, affecting the circuit’s ability to operate safely.

To address these issues, ensure that all appliances are properly grounded. Inspect circuit breakers for damage and ensure the GFCI is functioning correctly. If these steps do not resolve the issue, you might need to conduct a more thorough investigation of your electrical wiring.

Testing for Adequate Grounding

Testing your electrical panel’s grounding is crucial for safety. Using a multimeter, you can measure the resistance of the grounding system. A resistance reading below 25 ohms is ideal.

If your reading exceeds this threshold, consider enhancing your grounding system by adding a second ground rod. This reinforcement can significantly improve safety and reliability. Magnify Electric’s licensed electricians can assist you in verifying and improving your grounding system, ensuring all appliances and devices function correctly.

When to Call a Licensed Electrician

Knowing when to seek professional help is crucial for maintaining your electrical system. If you encounter persistent issues despite your troubleshooting efforts, contacting a licensed electrician is wise.

Major concerns like recurring ground-fault conditions or significant fluctuations in voltage should not be ignored. Professionals, like those at Magnify Electric, have the expertise to diagnose and fix these complex issues, providing peace of mind regarding your home or business’s electrical safety.

Maintaining a Safe and Effective Grounding System

To ensure your electrical systems operate safely and efficiently, consistent maintenance is essential. This involves regular inspections, upgrading outdated systems, and integrating grounding methods that keep pace with modern appliances. Each component plays a critical role in maintaining a reliable grounding network.

Regular Inspection and Maintenance

Regular inspections are vital for identifying potential grounding issues in your home wiring system. You should check all grounding connections, ensuring they are secure and free from corrosion. Pay particular attention to connections in receptacles, as poor contact can lead to electrical faults.

Consider scheduling annual professional inspections. Licensed electricians, such as those from Magnify Electric, can identify problems that may go unnoticed. Regular maintenance includes testing ground resistance and ensuring proper bonding between metal conduits and ground systems.

Document any findings and corrective actions taken during inspections. This history can help in future repairs or upgrades.

Upgrading Outdated Grounding Systems

Older grounding systems may not meet current safety standards. It’s essential to assess if your system includes outdated methods, such as inadequate ground rods or incomplete circuit pathways. Upgrading provides added safety and compliance with local electrical codes.

When modernizing your grounding system, consider using metal conduit for enhanced durability and conductivity. Your licensed electrician can recommend the best materials and methods based on your specific setup.

If you have added new appliances or high-demand equipment, evaluate if the upgraded system can handle the additional load. Magnify Electric offers expertise in upgrading these systems efficiently and safely.

Integrating Grounding with Modern Appliances

As technology advances, your grounding system needs to adapt. Modern appliances often require sophisticated grounding techniques for optimal operation and safety. Ensure that receptacles for these devices use ground-fault circuit interrupters (GFCIs) to provide additional protection.

Upgrading your system to include GFCIs, especially in kitchens and bathrooms, reduces the risk of electrical shock. Additionally, confirm that all metal conduits are properly bonded to your grounding system to prevent voltage anomalies.

Regular assessments will help integrate new technologies seamlessly. This proactive approach not only enhances safety but also prolongs the life of your electrical system. For more comprehensive support and expertise, rely on Magnify Electric, your go-to source for residential and commercial electrical work.

Frequently Asked Questions

Grounding an electrical panel involves specific codes and practices to ensure safety and compliance. This section addresses important queries regarding the requirements and procedures for grounding, as well as best practices.

What are the NEC requirements for grounding an electrical panel?

The National Electrical Code (NEC) outlines specific requirements for grounding. You must connect the grounding electrode system to the electrical panel using a proper grounding conductor. This typically includes grounding rods or other acceptable ground sources, as defined in NEC guidelines to protect against electrical faults.

Can you explain the process of grounding an electrical panel to a water pipe?

Grounding to a water pipe is feasible, but the pipe must be metallic and in direct contact with the earth. You will attach a grounding conductor to the pipe using a bonding clamp. Ensure that the connection is tight and meets local codes for grounding. Always check for any potential issues with your local authority.

What is the proper method to install a ground rod for a 200 amp service panel?

Installing a ground rod involves driving an 8 to 10-foot copper or galvanized steel rod into the earth. Position the rod vertically and connect it to the grounding system using a grounding clamp. For a 200 amp service panel, ensure the grounding conductor is appropriately sized based on NEC requirements to handle potential fault currents.

When should the ground and neutral be separated in a main panel, and how is it done?

Ground and neutral should be separated beyond the main service panel when they enter subpanels. To separate them, remove the bonding screw or strap that connects the ground and neutral bus bars in the panel. Ensure that each bar has separate connections to their respective systems to prevent electrical shock hazards.

How do you ensure proper grounding of both a meter base and an electrical panel?

To ground a meter base and an electrical panel, ensure that both are connected to the same grounding electrode system. Use a grounding conductor that complies with NEC standards. Verify that connections are secure and check the grounding resistance to ensure safety and effectiveness.

What are the steps in creating a grounding diagram for a sub panel?

Creating a grounding diagram for a subpanel includes identifying all grounding conductors, their connections, and grounding electrodes. Start by marking the main panel and subpanel locations. Next, illustrate how the ground is connected to grounding rods or other electrodes while ensuring compliance with local codes. This diagram aids in visualizing effective grounding practices.

If you need assistance with any electrical work, including grounding, rely on Magnify Electric. Our licensed electricians are ready to help with all your residential and commercial electrical needs.