A junction box is a crucial component of your electrical wiring system. Its primary purpose is to protect and organize electrical connections, preventing damage, exposure, and overheating. By serving as a secure enclosure where wires meet, junction boxes help maintain the safety and efficiency of your home or business’s electrical setup.

Understanding the function of junction boxes can empower you to make informed decisions about your electrical system. At Magnify Electric, our licensed electricians are dedicated to ensuring your electrical needs are met with expertise. From simple lighting changes to more complex installations, we provide comprehensive support tailored to your residential and commercial requirements.

Whether you’re upgrading your current system or addressing specific electrical issues, knowing about junction boxes can enhance your overall understanding of safety measures within your wiring system. When you choose Magnify Electric, you gain access to knowledgeable professionals committed to delivering top-notch electrical services.

Understanding Junction Boxes

Junction boxes are critical components in electrical systems, designed to ensure safe and efficient electrical connections. These boxes facilitate wire management and provide protection against potential hazards. Below are the key elements that define junction boxes, their varieties, and their applications.

Definition and Basic Functions

A junction box is an enclosure used to house electrical connections, splices, and terminations. Its primary purpose is to protect wiring from damage and reduce the risk of electrical shock.

Inside a junction box, various wires can connect, ensuring a secure and organized setup. The box not only safeguards these connections but also helps prevent short circuits and electrical fires.

In addition to protecting connections, junction boxes can also serve as a point for future electrical modifications. Whether you’re performing minor lighting changes or installing new fixtures, Magnify Electric’s licensed electricians can assist with the installation and maintenance of your junction boxes to ensure optimal safety and functionality.

Different Types and Materials

Junction boxes come in various types and materials to meet specific electrical needs. The two most common materials are metal and plastic.

Metal junction boxes provide durability and are often used for outdoor or industrial applications. They offer excellent protection against physical damage and are typically grounded.

Plastic junction boxes, on the other hand, are lightweight and non-conductive. This makes them ideal for use in residential settings where moisture is not a concern.

Additionally, there are fiberglass junction boxes that offer a blend of strength and lightweight characteristics, suitable for harsh environments. Each type serves distinct applications, so choosing the right one is crucial.

Standard Sizes and Their Applications

Junction boxes are available in various sizes to accommodate different wiring configurations. Common sizes include 4×4 inches, 4×2 inches, and octagonal designs, among others.

Smaller boxes are suitable for standard light fixtures and small electrical connections. In contrast, larger boxes can hold more wiring and splices, making them ideal for complex installations.

Selecting the right junction box size is vital to ensure safety and functionality. An oversized junction box may take up unnecessary space, while an undersized box might lead to overheating or electrical hazards.

For any electrical work, including selecting the appropriate junction box, trust Magnify Electric to provide expert guidance and support for your residential and commercial projects.

Installation and Usage Guidelines

Proper installation and usage of junction boxes are crucial for safe electrical connections. Understanding the right techniques will ensure durability and compliance with building standards.

Mounting and Positioning

When mounting junction boxes, choose locations that are accessible for future inspections or repairs. Consider the type of surface; secure the box to framing members, typically within walls or ceilings. Ensure that the box is flush with the wall surface to facilitate easy installation of drywall. Use screws or anchors specifically designed for the material you are working with to provide strong support.

Position the junction box close to the electrical panel if possible. This reduces the length of wire runs and minimizes voltage drop. Always leave some slack in the wires for adjustments during future electrical changes.

Wiring and Connection Techniques

When wiring, you will typically use wire nuts to secure connections. Strip the ends of the wires to expose enough copper for a solid connection. Always connect wires of the same color—black to black (or hot), white to white (or neutral), and green or bare to ground.

Make sure all connections are tightly twisted and secure. Loose connections can lead to arcing and potential fire hazards. Consider using heat shrink tubing for added protection against moisture and accidental contact. Following the National Electrical Code is essential to ensure that your installations meet safety standards.

Compliance with Building Codes

Ensure your junction box installations comply with local building codes. Consult the National Electrical Code (NEC) for guidelines on the number of wires allowed per box and the appropriate rating based on the box’s location and use.

Each jurisdiction may have additional regulations, so check with local authorities. Proper labeling of junction boxes can also enhance safety and make future maintenance easier. Furthermore, using a licensed electrician like Magnify Electric guarantees that your installations meet all requirements, providing peace of mind for both residential and commercial needs.

Safety Measures and Standards

Ensuring safety in your electrical systems involves key measures and adherence to specific standards. Understanding how to prevent hazards and properly implement grounding and insulation can drastically reduce risks associated with junction boxes.

Preventing Electrical Fires and Shorts

To minimize the risk of electrical fires and short circuits, it’s essential to use junction boxes that are compliant with safety standards. These boxes protect connections by enclosing them in a durable casing, which shields against dust, moisture, and physical damage.

Using the appropriate junction box for your application is critical. For instance, a box rated for wet locations should be used in areas exposed to moisture. Regularly inspect your electrical systems to identify and replace any damaged wires or connections.

Adhering to the National Electrical Code (NEC) is vital for residential and commercial safety. These codes provide guidelines on the placement and installation of junction boxes to help prevent overheating and potential fire hazards.

Grounding and Insulation Considerations

Grounding and insulation have a significant impact on electrical safety. Proper grounding ensures that excess electricity has a safe path to the ground, reducing the risk of electrocution. Make sure to use a dedicated ground wire that connects to the junction box.

Insulation plays a critical role in preventing electrical shorts. Ensure that wire connections are well insulated and securely fastened. Poor insulation can lead to exposed wires and increased fire risk.

Magnify Electric emphasizes the importance of rigorous adherence to these safety measures in all our projects. Our licensed electricians are well-versed in current electrical codes and standards, ensuring your electrical systems are safe and reliable for your residential and commercial needs.

Applications in Different Environments

Junction boxes serve crucial functions in various settings, protecting electrical connections and ensuring safety. Their design and features cater to specific needs depending on whether they’re used indoors or outdoors and in different types of buildings.

Indoor vs. Outdoor Uses

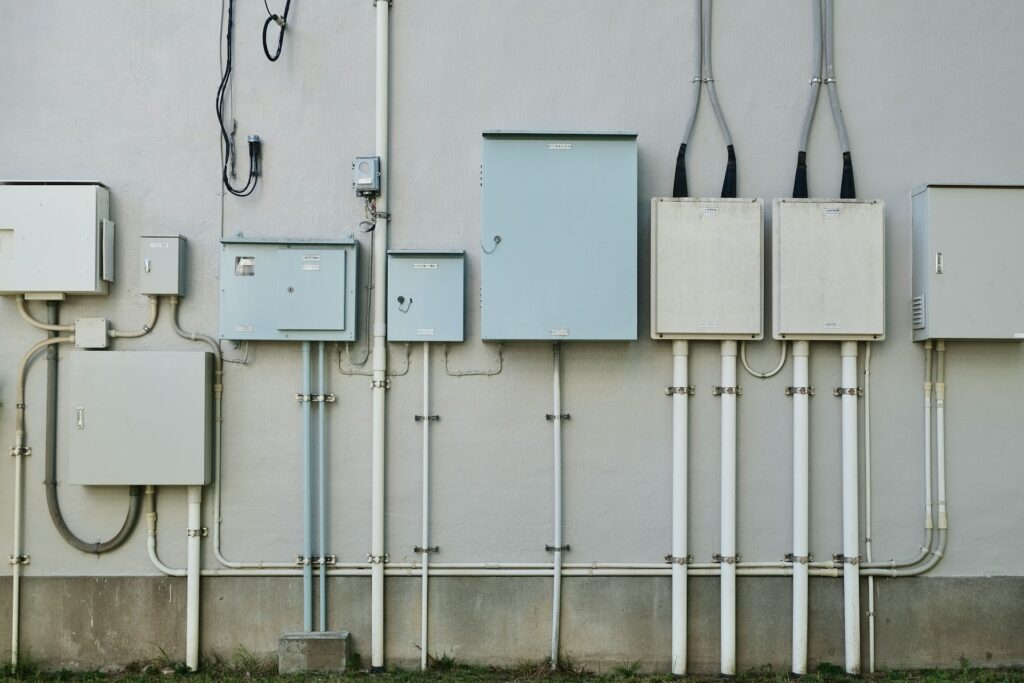

Indoor junction boxes are typically installed in dry, controlled environments. They protect wire connections in residential spaces, commercial buildings, and offices. Common applications include wiring for lighting fixtures and outlets. In contrast, outdoor junction boxes must withstand environmental elements. These are often weatherproof and designed to meet specific NEMA ratings or IP ratings to ensure durability and safety. Weatherproof junction boxes prevent moisture and dust ingress, crucial for maintaining functionality in unpredictable weather. Understanding the parameters for installation will help you choose the right type of junction box for your specific setup.

Residential, Commercial, and Industrial Settings

In residential environments, junction boxes are essential for connecting lighting, outlets, and appliances safely. They come in various sizes and shapes to suit different needs, ensuring reliability over time. For more extensive demands, commercial settings also utilize junction boxes but may require more robust designs for heavy machinery or inconsistent loads. You can rely on Magnify Electric for expert services in both sectors, ensuring installations meet safety standards and functionality.

In industrial applications, junction boxes connect complex instrumentation and machinery controls, providing crucial pathways for electrical signals. Ensuring proper installation and maintenance is vital to prevent costly downtime and injuries. Consider weatherproof options in these settings, especially if they’re located near open doors or windows that could expose them to industrial contaminants.

Maintenance and Troubleshooting

Proper maintenance and troubleshooting of junction boxes are essential for ensuring their reliability and the overall safety of your electrical systems. Regular inspections and prompt issue resolution can prevent major problems, such as electrical fires or system failures.

Regular Inspection and Upkeep

To maintain the integrity of junction boxes, conduct regular inspections. Schedule these evaluations at least twice a year, focusing on visual signs of wear or damage. Look for:

- Cracked or damaged covers: These can expose live wires.

- Signs of corrosion: Rust can compromise connections.

- Secure connections: Ensure that wires are tightly secured; loose connections can lead to voltage drops.

Using a voltage tester during inspections can help confirm that systems are operating at the correct voltage. When you notice any issues, it’s best to consult professionals like Magnify Electric. Our licensed electricians can help you ensure your electrical systems remain safe and efficient.

Identifying and Resolving Issues

When troubleshooting, ensure that the power is turned off to avoid accidents. After this, inspect the junction box for the following common issues:

- Overheating: This may indicate overloaded circuits or loose connections.

- Burnt wires: If you observe any burnt or singed wiring, immediate action is needed.

To resolve these problems, tighten any loose connections and replace damaged cables. If complications persist, seek professional assistance. Magnify Electric specializes in identifying and resolving these common mistakes and can help maintain the reliability of your electrical distribution systems. Addressing issues promptly not only protects your systems but also enhances your safety.